COMMON CHALLENGES OF FIRE DOOR HANDLE

Fire Resistance Failure & Evacuation Risks

Emergency Operation Difficulties

Durability Issues & Rising Maintenance Costs

Compatibility Issues & Installation Risks

DIROCK FIRE RATED DOOR HANDLES

Our fire compliant door handles are engineered for public buildings, made of 304 stainless steel (anti-corrosion/wear/heat resistant), compliant with European standard EN 1906/ DIN 18273/ DIN 18255. Our self-owned factory supports mass production, customization and fast delivery.

→ Explore DIROCK stainless steel fire door handles now!

Grade 3 Fire Door Lever Handle

Grade 4 Fire Door Lever Handle

WHY CHOOSE OUR FIRE DOOR HANDLES?

Compliance Guaranteed

EN 1906 certified, dimensions in accordance with DIN 18273/DIN 18255.

Fire-tested compliant with EN 1634-1, suitable for timber/steel fire doors.

Reliable Mechanical Performance

200,000-cycle durability tested.

Exceptional corrosion/abrasion resistance: 304 stainless steel(240h salt spray tested).

Sturdy construction ensures safety and durability.

Versatile

Designs

Diverse styles for broad applications.

Precise compatibility with other European-standard hardware.

Graded solutions: Grade 3 & 4 door handles for tailored needs.

Manufacturing Excellence

ISO 9001:2015 (UKAS) certified production.

100,000-unit monthly capacity for bulk/custom orders.

APPLICATION

DIROCK fire resistance door handles are widely used in hotels, healthcare facilities, airports, schools, malls, and other large public buildings. Grade 4 handles serve demanding venues (e.g., football stadiums, offshore installations, barracks,etc).

WHY PARTNER WITH US?

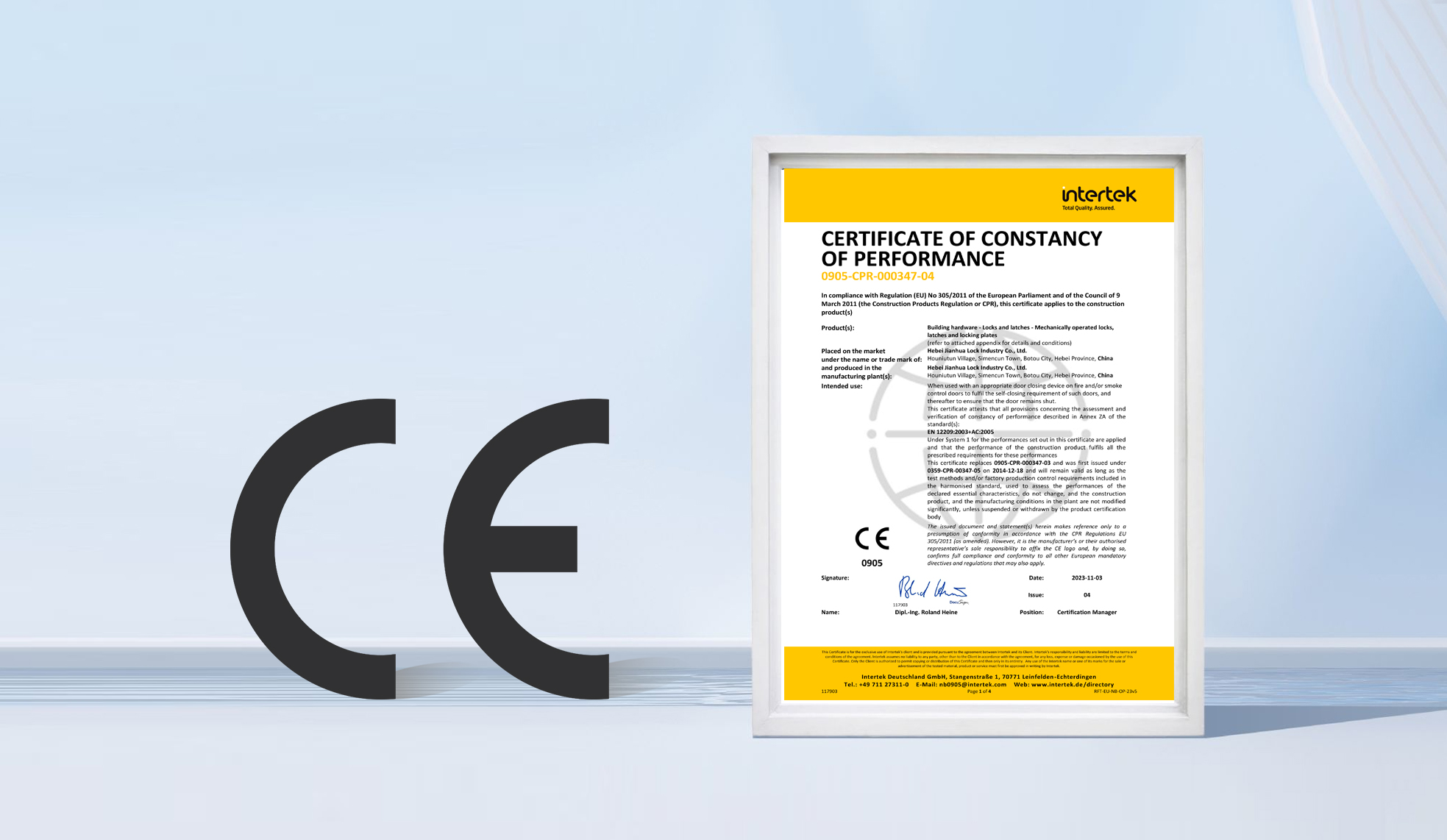

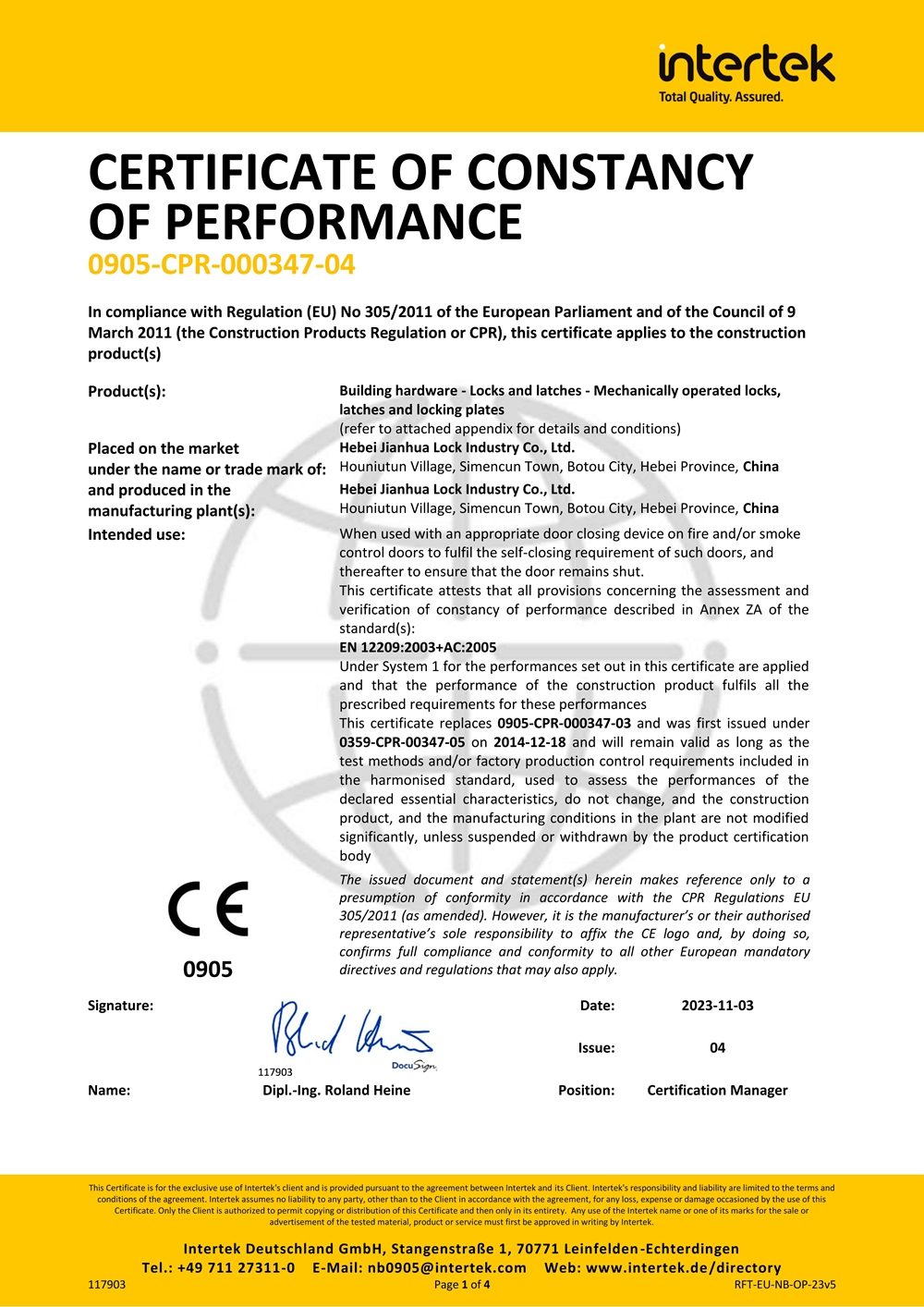

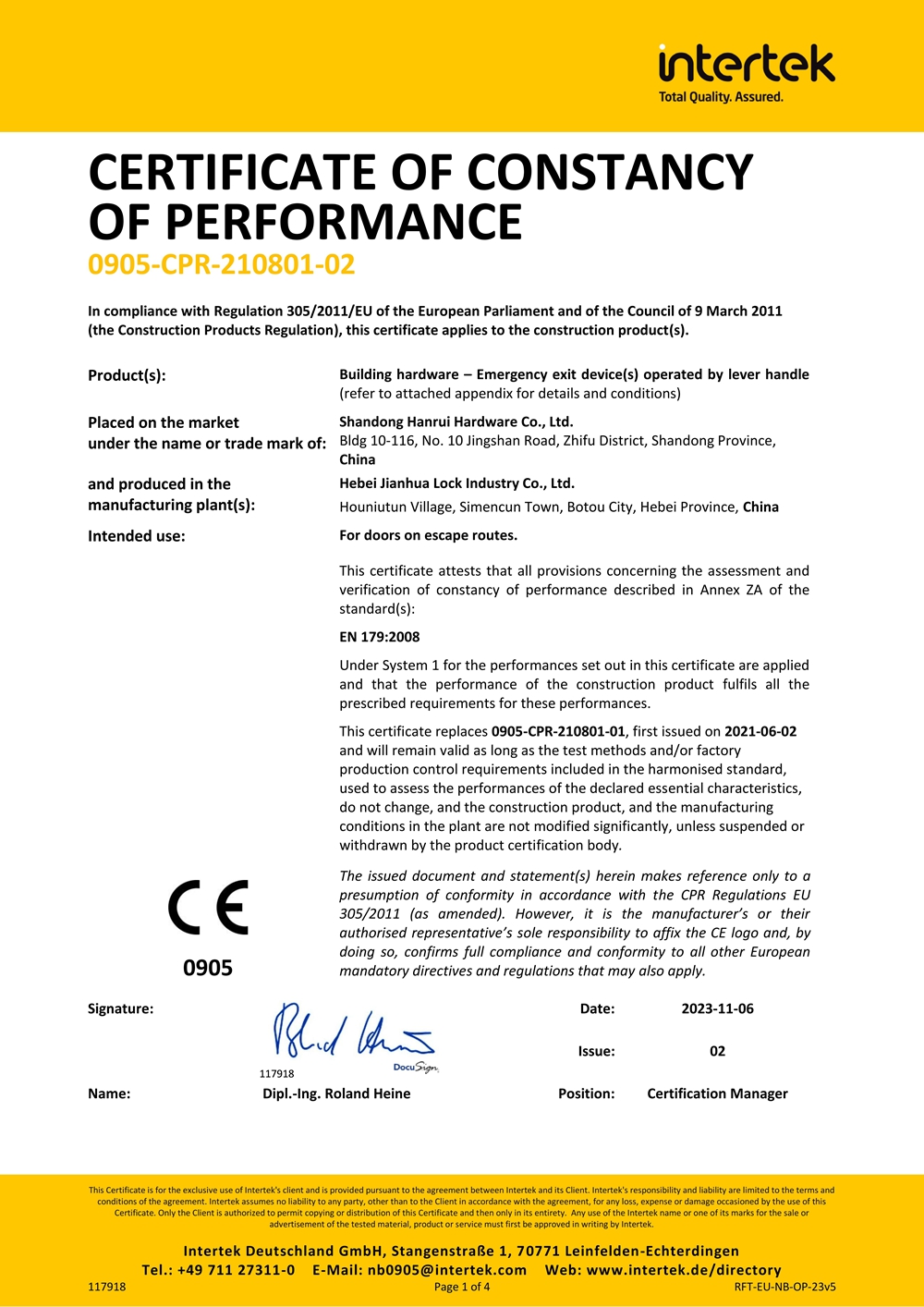

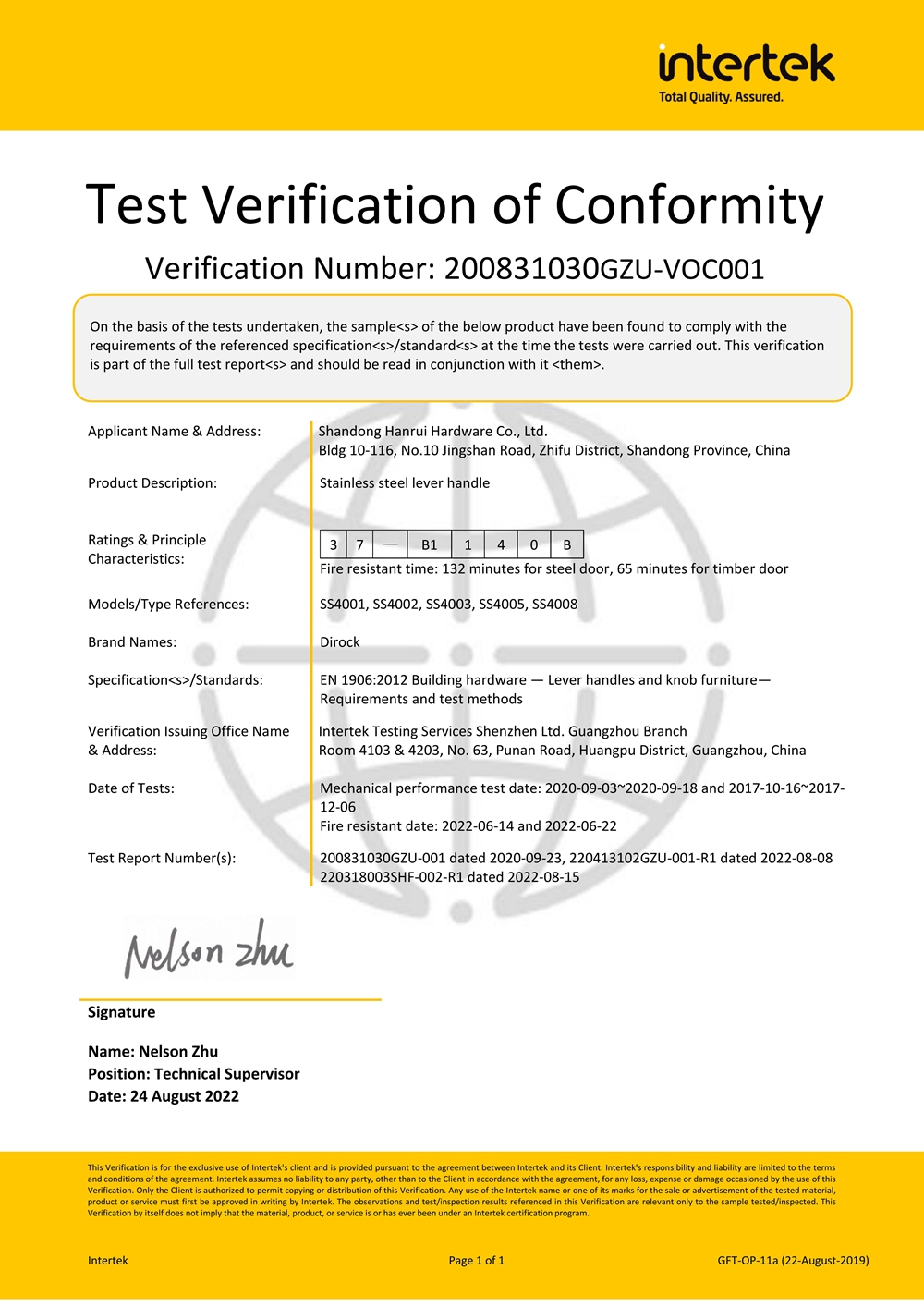

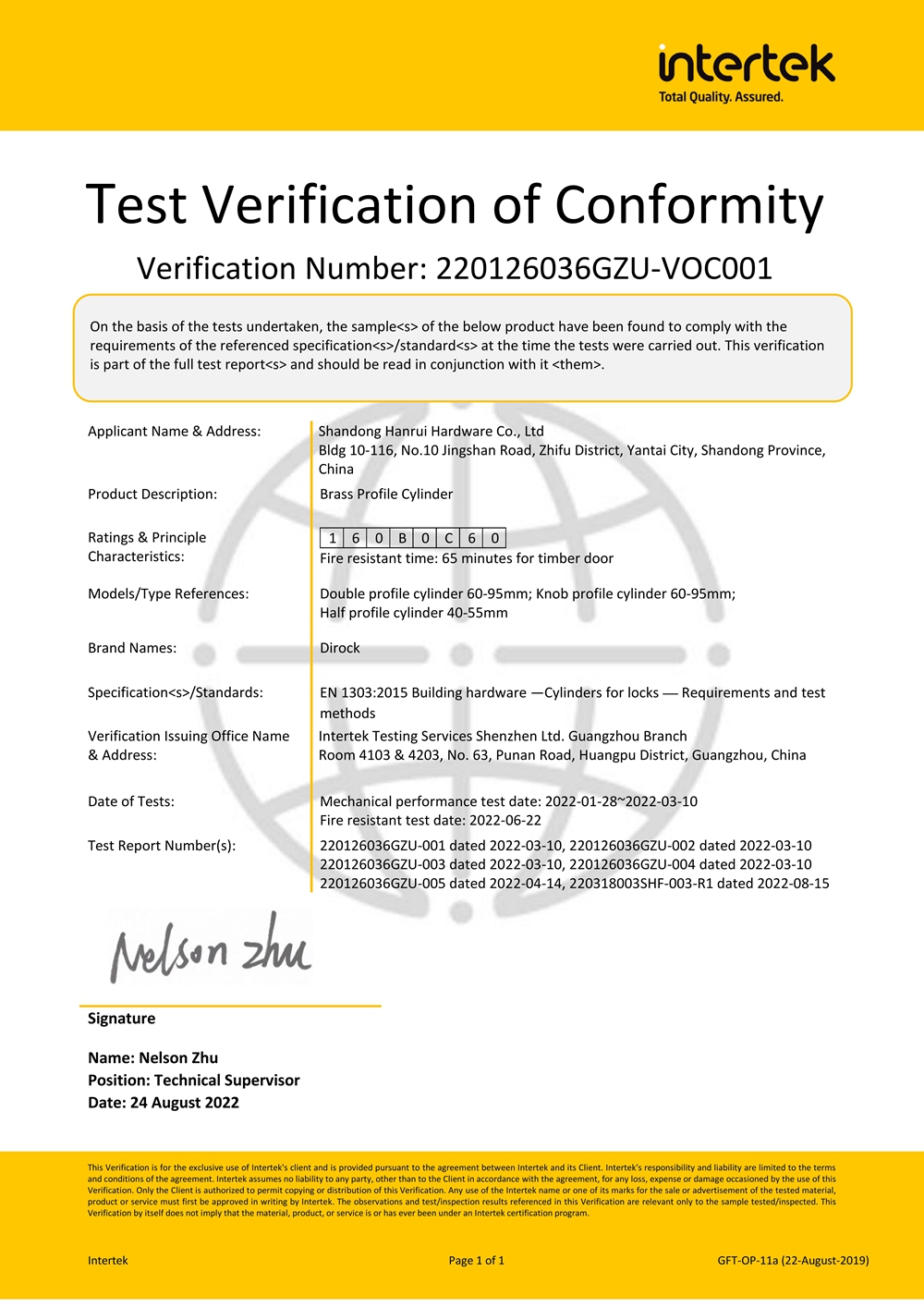

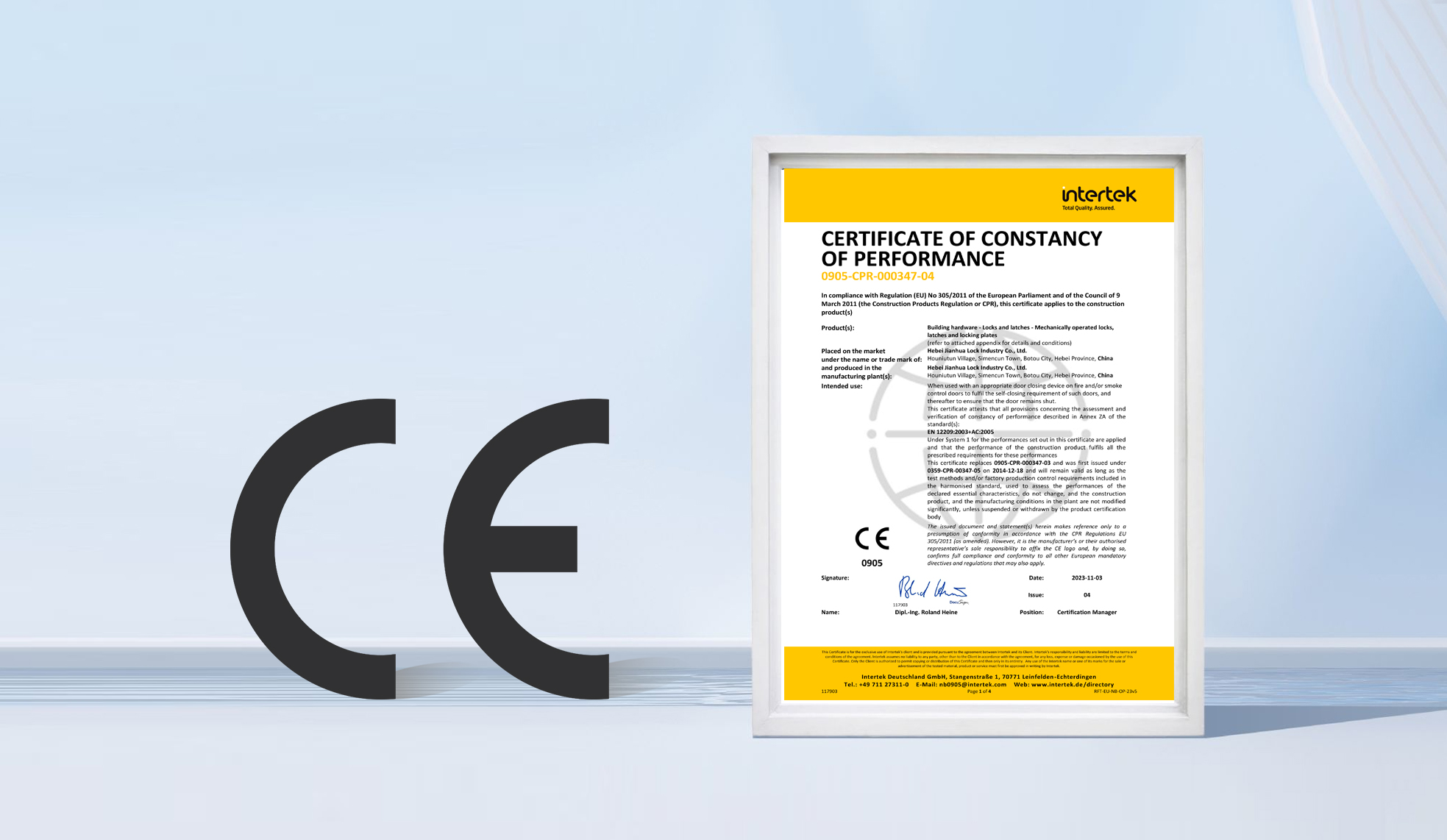

Standards & Certifications

Products: Obtain CE certification (Intertek & Warrington)

Factory: Three system certifications ISO 9001 (Quality)| ISO 14001 (Environment)| ISO 45001 (Safety)

Manufacturing Capabilities

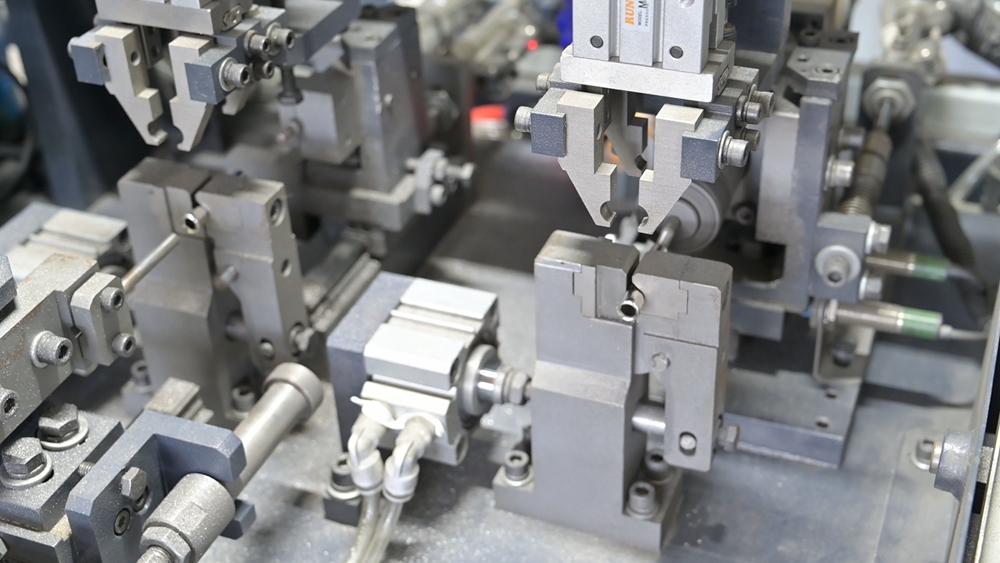

Self-owned factory,stable funding with advanced automated production lines

Stable capacity, average monthly production capacity of 200,000 locks, 100,000 handles, supporting OEM customized services.

Quality Assurance

Relying on ISO 9001 to establish production control system (FPC), strictly controlling every link from raw material procurement to product delivery, ensuring quality consistency and full traceability.

In-house laboratory equipped with testing facilities for precise inspection.

ISO CERTIFICATION

PRODUCT CERTIFICATION

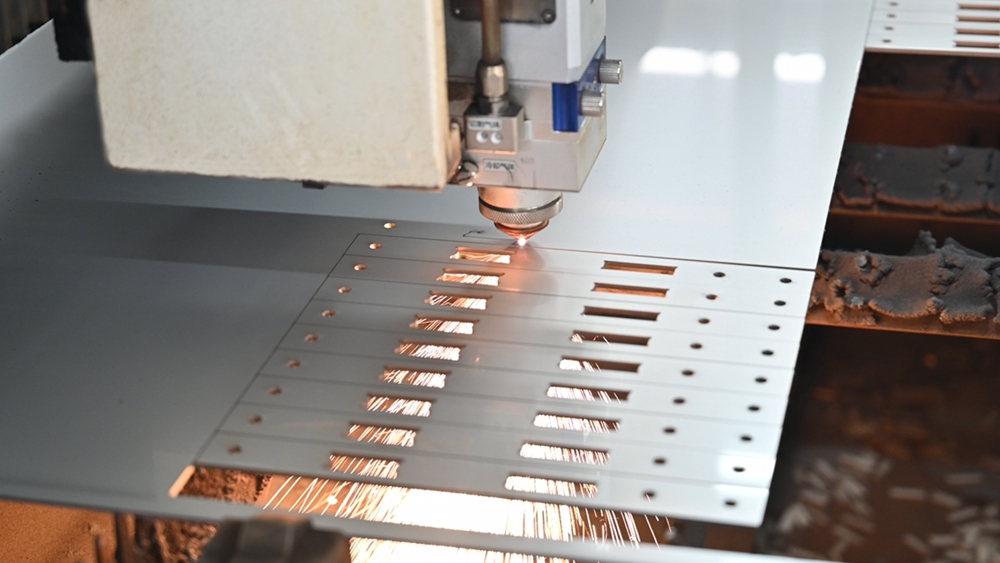

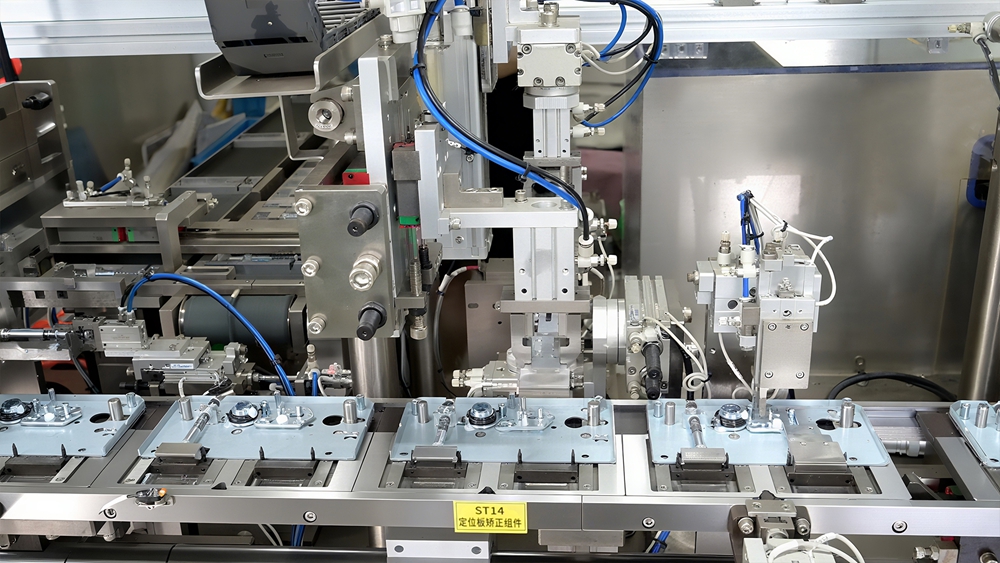

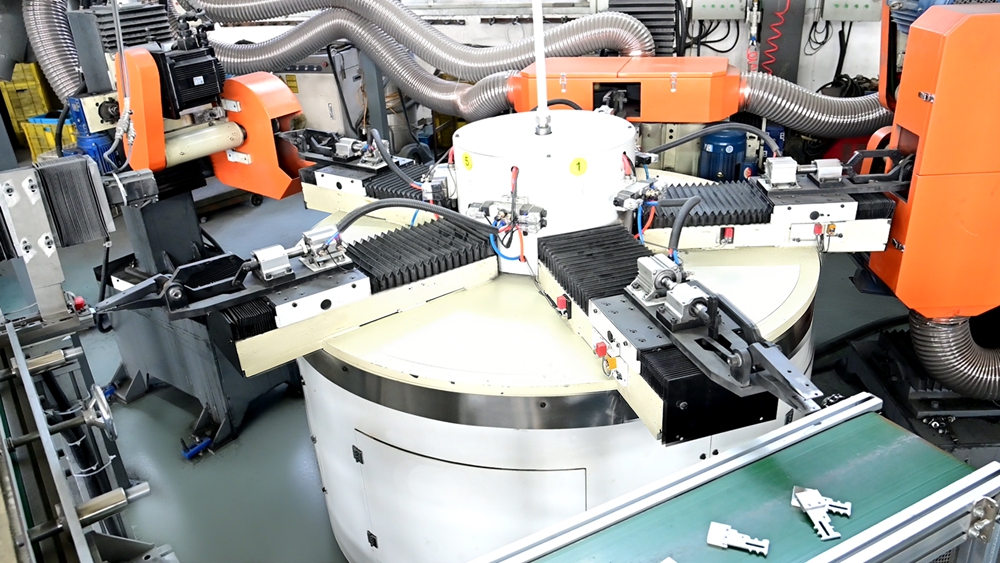

AUTOMATED PRODUCTION EQUIPMENTS

Laser cutting

Lock assembly

Brushing

Lock assembly

Brushing

Tapping

We're Here to Support Your Projects.

FAQs

1. Do door handles need to be fire rated?

Only handles on fireproof doors must be fire resistant (EN 1634-1). Moreover, their fire rating must match that of the door. Regular doors can use standard handles.

2. Do fire doors need special handles?

Yes, fire doors require special fire-rated handles. If the doors are fire rated, the door handle must comply with the appropriate standard, such as EN 1906, EN 1634-1( EU standard). These handles are designed to withstand high temperatures and maintain the door's fire resistance, thereby effectively protect people’s lives and property.

3. What makes a door handle fire rated?

A fire-rated door handle is constructed from materials with high melting point that offer high heat resistance and durability. It must meet specific fire resistance standards, such as EN 1634-1, and be tested to withstand fire for a specified period (e.g., FD30 for 30 minutes or FD60 for 60 minutes). The handle also maintains operability after heat shock, ensuring it can still function effectively in extreme conditions.

For more detailed information on fire door handles, please refer to our comprehensive guide:

RELATED BLOGS

-

CE certification is the mandatory passport for fire door hardware entering the EU market, but its significance extends far beyond a mere mark. This article outlines the core regulations, key procedures, stakeholder responsibilities, and common misunderstandings of CE certification, providing clear aProduct

CE certification is the mandatory passport for fire door hardware entering the EU market, but its significance extends far beyond a mere mark. This article outlines the core regulations, key procedures, stakeholder responsibilities, and common misunderstandings of CE certification, providing clear aProduct -

The Big 5 Construct Saudi successfully took place at the Riyadh Front Exhibition & Conference Center from January 18-21, 2026. As Saudi Arabia's first major building industry event of the year, it stands as one of the Middle East's most influential professional platforms, focusing on building fit-ouExhibition

The Big 5 Construct Saudi successfully took place at the Riyadh Front Exhibition & Conference Center from January 18-21, 2026. As Saudi Arabia's first major building industry event of the year, it stands as one of the Middle East's most influential professional platforms, focusing on building fit-ouExhibition -

Fire door hardware plays a critical role in the overall performance of a fire-rated door assembly. While product selection and certification often receive significant attention, regular inspection and ongoing maintenance are equally essential to ensure that fire door hardware continues to function aProduct

Fire door hardware plays a critical role in the overall performance of a fire-rated door assembly. While product selection and certification often receive significant attention, regular inspection and ongoing maintenance are equally essential to ensure that fire door hardware continues to function aProduct

CONTACT US

Thank you very much for your interest in us! If you want to contact us, you can contact us through the following methods: